The Ithaca Model 37 details here are based on information provided online in Wikipedia, and in a 2005 article by Todd Watts. These details apply specifically to guns produced by the original company pre-1975. There may have been some changes since.

The 37 is a slide or pump action repeating shotgun design that in itself is not that much unlike many other repeating shotgun models that have come and gone. Its chief competitors have traditionally been the Remington 870, Winchester’s Model 12 and 1300, and Mossberg’s Model 500. All of these, as well as dozens of others that have competed with the 37, do essentially the same thing. But the 37 is unique enough to hold a special niche and following in the U.S. market.

Things the 37 has going for it are quality, simplicity, reliability, maintainability, and handling/usability. The double-fingered shell carrier provides positive control of the round, from magazine to chamber. The shell load/eject port is on the bottom, protecting the action from environmental fouling, protecting the shooter from potential firing byproducts, and increasing usability, since the mechanism is equally suited to right- and left-handed shooters. Further, the safety lock can be installed in right- and left-handed configuration.

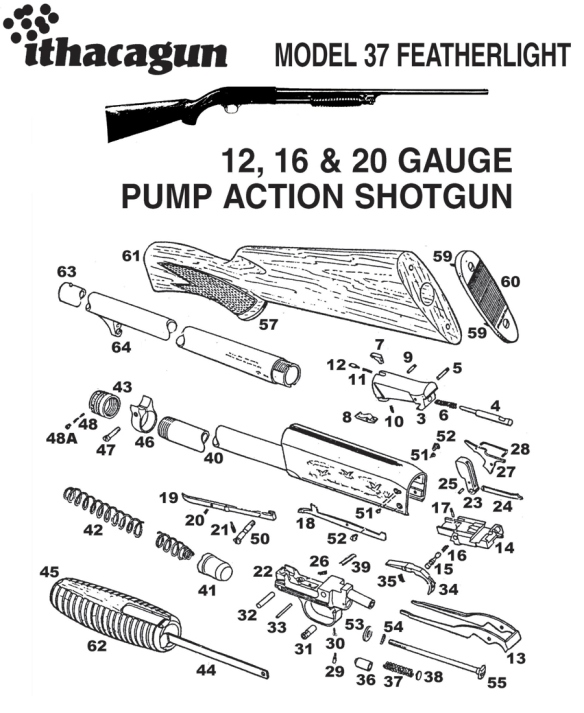

The barrel is attached to the receiver by an interrupted thread. It is easily removed for cleaning by unscrewing the knurled plug on the end of the magazine tube, turning the barrel 90 degrees, and pulling it off the receiver. The Featherlight was a pound lighter than any of the other repeating shotguns of its day, weighing only 5.75 lbs for the 20 gauge and increasing to 6.5 lbs for the 12 gauge, unloaded. The 16 gauge weighs a scant 6 lbs, which makes for an easy handling shotgun in the field.

The Model 37 has the fewest parts of any pump shotgun, promoting reliability and creating a smooth, light, positive action. The short stroke and very solid sound and feel of the Ithaca action is a delight to me; it is claimed to be unsurpassed by any pump gun in this regard. The trigger consistently pulls at 4.5-5 lbs force and has no creep.

All this quality derives from inspired design, strong materials, and expert machining. The 37 has no stamped or cast metal parts, but is instead manufactured from machined forged steel parts, as strong as they can be for their size. The external steel is blued for corrosion resistance and appearance. Solid American walnut is used for the machined stock and concentric grooved forend. The standard field grade 37s have been offered in barrel lengths of 26”, 28” and 30”. For years the 37 was only configured for 2 3/4” shells in 20, 16, and 12 gauge chamberings. Production after serial number 855,000 accepted 3” 20 and 12 gauge shells.

All field grade 37s come with two engravings on the sides of the receiver. On the left side is an upland game scene and on the right side is a waterfowl game scene. Both were drawn by Bill McGraw, the most well known of the Ithaca factory engravers. The top of these receivers was given a matte finish in the early models to reduce reflection.

Loading the Ithaca 37 involves inserting shells through the bottom loading/ejection port and pushing them forward into the magazine until retained by the shell stop. The slide release is pressed and the slide retracted completely then pushed forward. Pulling the trigger fires the gun and releases the slide for reloading.

Vintage shotguns such as the Model 37 and the Winchester Model 12 do not disconnect the sear from the trigger during slide operation, allowing the hammer to be released to travel forward right behind the bolt as it closes, if the trigger is held back during cycling. This allows the original 37 to ‘slam fire’ just after the bolt rotates up to lock the shell in the battery recess of the upper receiver. This ‘feature’ has little real use for sportsmen, and increases the risk of accidental firing during operation, so care in operation is required. A disconnect was added to later versions as a safety feature. Using a vintage model without disconnect, a skilled shooter of the 37 can cycle the action fast enough to nearly keep pace with a semi-automatic shotgun, albeit probably not regularly hitting the target.

The Model 37 action centers around its spring steel carrier. The carrier is shaped like a long fingered two-prong fork. It pivots down to grip the fresh shell between its fingers as the shell stops release a shell from the magazine. Then it pivots the fresh shell up to position for the bolt to force forward off the carrier’s grip. In reverse, the bolt extracts the fired hull into the grip of the carrier, which then rotates the spent hull downward and pulls it from the extractors on the bolt. The spring steel of the carrier then literally throws the spent hull from its grip and out the bottom of the receiver just as the shell stops release a fresh shell onto the just emptied fingers of the carrier to repeat the process. The carrier’s timing is essential for the 37 to operate properly and any damage to this part will make the gun fail to function.

The easy takedown of the 37 facilitates basic maintenance. First the gun is checked to see that it is indeed unloaded. To unload the magazine, the easiest method is to manually depress the shell stop part inside the right side of the frame and easily reached from the open loading/ejection port. This will allow the shells to eject from the magazine.

Second, the slide is retracted and the magazine nut is rotated clockwise as if tightening the nut. This direction is strange to most shooters used to unscrewing the magazine nuts from other modern repeaters. Once the nut stops, grip the barrel and rotate it counter clockwise a quarter turn and remove it straight forward. That is all there is to it for routine maintenance.

If the magazine is to be cleaned, the magazine nut can be unscrewed by reversing the earlier direction of the turn to take it off, thus releasing the magazine spring and follower as well as any plug installed. Further disassembly is the job of a gunsmith because any damage to the few parts can cause other parts to become damaged. It is very important to note that any time the magazine nut is to be moved to remove the barrel, the action must first be opened at least partially to disengage the two extractors from the barrel or they will break as the barrel moves.

The gun’s slide lock timing can be checked by cycling the action. Pull the trigger and keep it held back while holding the gun upside down and slowly cycling the action. To time properly on guns without disconnectors, the bolt must close completely slightly before the hammer falls to strike the firing pin. It does not matter how fast this happens as long as the bolt is closed completely before the hammer strikes. On guns with a disconnector, the trigger will have to be released and then pulled again in order to release the hammer.

The carrier is seen inside the open loading/ejection port and is supposed to be springy. Lightly squeeze the two prongs a short way and release to see that they return to their original shape. If cracked or broken they will not spring back properly and thus the gun will certainly need repair. The spring tension of the carrier is normally weak, so that you can press it back in the receiver a little ways with ease.

The two shell stops work together and will wear out with a lot of use. They are supposed to have sharp fronts and over time they round off or break which causes shells to eject from the magazine prematurely or fail to eject reliably. These are made of spring steel and cannot be easily repaired so it is best to replace them if they are worn. The left stop is a lever that moves left and right while the right stop moves up and down.

To disassemble the gun further, it is important to remember to first back out the stock bolt screw before any attempt to unscrew the trigger plate screw is made. The stock bolt screw rests in a slight recess in the shank of the trigger plate screw and if the trigger plate screw is forced back while the stock bolt screw is in the recess damage to both parts will result.

The safety button typically works for a right-handed shooter but Ithaca offers a left-handed version for installation. One must be certain which version is in any 37/87, when first handled. This is a standard trigger-block safety device that firmly blocks trigger travel when engaged.

To test the slide to hammer timing, insert a live round or one that is loaded only with a primer. The gun must be held down range and the trigger held back as the action cycles a round slowly into battery. If the timing is correct the bolt will lock just as the hammer falls and the gun will fire. But, if timing is off due to worn or damaged parts, the hammer will fall a moment too soon and will strike the bolt at an angle and fail to strike the firing pin, so the gun will not fire. For normal use this timing problem isn’t a big issue, but in case the gun is to be used for rapid fire (such as for law enforcement) this flaw can cause the gun to fail to fire at the wrong time.